- Emblematic worksite

Restoration of the Notre-Dame d’Auffay collegiate

The Notre-Dame d’Auffay collegiate is an old collegiate located within the municipality of Val-de-Scie (formerly Auffay), in the Normandy region of France. Classified as a Historic Monument, the building was originally constructed in the 11th Century. Since 2017, restoration works have been underway on the site. Today, the church’s spire is undergoing large-scale restorative works. […]

The Notre-Dame d’Auffay collegiate is an old collegiate located within the municipality of Val-de-Scie (formerly Auffay), in the Normandy region of France. Classified as a Historic Monument, the building was originally constructed in the 11th Century.

Since 2017, restoration works have been underway on the site. Today, the church’s spire is undergoing large-scale restorative works. This restoration operation represents a major technical challenge, aiming to restore the monument to its former glory.

A technical challenge 72 metres up

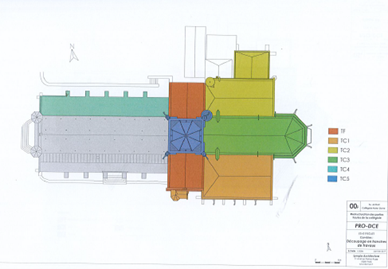

The renovation of the spire of Notre-Dame d’Auffay collegiate church is the final step for restoration works that began six years ago. To successfully complete this last challenge, the teams used meticulous planning with six distinct work phases: One firm instalment and five conditional instalments.

The final step, which consists in the full renovation of the spire, is considered to be the most complex in terms of technicality, material volume and height, with the use of 36 levels of scaffolding rising to 72 metres in height. This latter operation is expected to take at least six months and constitutes a crucial step in the preservation of this incredible historic monument.

This phase consists in installing the top section of the spire, made of stone, to reconstruct it identical to the original. The metal cross and cockerel also need to be changed.

Custom solutions for a large-scale project

Tubesca-Comabi was chosen for this project, and has been entrusted with supplying, assembly and dismantling scaffolding throughout the works process.

To meet the specific needs of this project, external, M368 multi-directional scaffolding, measuring 1 metre in width, was used.

The greatest technical prowess was achieved for the spire, where freestanding scaffolding was installed up to a height of 25 metres.

Plus, internal scaffolding was installed in the bell room and another in the spire, based on a platform, in order to reinforce the external scaffolding and to allow the stonemasons to work from both inside and outside the monument.

Protection nets were installed around the steeple, with two supply winches at 53 metres high. 70-metre UNISTEP stairs were also used for the exterior to facilitate workers’ access.

Thanks to this equipment, the restoration teams have been able to work safely and efficiently.

Technical and logistical challenges to overcome

This restoration project involved several significant restraints, in terms of both technicalities and logistics:

- The 25-metre freestanding external scaffolding for the spire required the installation of specific equipment, allowing for safe work at a height of 72 metres.

- The feet of the other scaffolding were based on the roofing of the transept and of the nave, meaning that additional precautions had to be taken to avoid causing any damage during the work.